Thursday, 24 December 2020

On the Road

Sunday, 8 November 2020

IVA Test and Beyond

Remember your school days? I do. The only highlight was getting a star for my homework. Sometimes it was a red star, occasionally a silver star and rarely, a gold star. Although most teachers made do with a '✔ V. Good'. But sometimes the homework came back with SEE ME scrawled in angry red letters across the bottom of the page, and it was never because teach wanted to congratulate me on my work.

So, it is now again time to hand in your homework for marking.

The AK members area on their website has very useful examples to help you fill in the forms to request the IVA test. Also a list of all the documents, photos, invoices etc etc you will need. All these forms are available on .gov.uk websites.

You should have already acquainted yourself with the IVA manual. Read it. Every word of it. I didn't and was surprised when the examiner said he cannot test the car as I didn't have a full tank of fuel. Fortunately he allowed me to whizz down the road ("it is insured and on it's way to the IVA station, Officer") and fill up at a petrol station.

Before the IVA I arranged to have the car picked up by a local garage and have it put through an MOT test. My thanks here go to Simon Graham Auto Service Centre of Hampsthwaite. Simon knows a thing or two about kit cars and IVA tests and was happy to check the car over. The main things are the ones you cannot test yourself, emissions, brake efficiency including the handbrake, and headlight aim. As well as that it is useful to have the car up on a ramp so you can take a good look underneath without having to lay on your back with the chassis two inches from your nose. Simon checked all over, steering, suspension, checked nothing was rubbing or loose etc. The garage is located half way along a mostly deserted country road so I was able to run the car up the road with an old sat nav to check the speedo. At 30mph the speedo indicated 27mph.

When you have a date for the IVA, call AK and request the IVA loan kit. It comprises a few things you will need to bolt on to enable a pass.

There are so many things that can catch you out. Make sure you have an orange label and words about using DOT4 fluid from a sealed container on the brake reservoir. Cover up the wiper motor with foam so it doesn't have hard or sharp edges showing. A full fuel tank helps. Have some sort of cover over the bonnet lock edges. My tester mentioned he thought the fog light button should have a different colour light to that of the other light switches in order to differentiate it. If you have Savage switches they may be all blue. It wasn't a failure in my case but do be aware that some of these IVA items are open to interpretation.

Speaking of which, take the strange case of the fog light operation. The majority of people I spoke to had this view: It is a requirement that having switched on the fog light it must not come on again when the lights or the ignition are switched off and back on again unless the fog light switch/button is re-engaged. That is to say even if the fog light switch/button is engaged, the fog light must not come on when the ignition or main lights are switched on. It saves you from permanently driving around in clear weather with the rear fog light on. Now, AK and everyone who has put their AK Cobra through a test find otherwise. Car Builder website and a few others will tell you it is required and sell you a device to make it happen. It is probably a one shot electrical system that needs a reset after the power is cut, the reset being the fog light switch being set off/on.

The IVA manual does indeed have something to say about this and what it says is that it is 'acceptable' for this arrangement to be in place, not that it is actually required. Anyway, I got a pass without it so it does indeed seem to be an acceptable operation, not an actually required one. I wish they would just take reference to it out altogether but I guess they like to give their technical writers something to do.

On the day I suggest you take along a few tools, a spare set of bulbs, some spare fuses, gaffer tape, tie wraps and anything else you think may be useful. The thing is that the IVA test chaps are usually quite reasonable and if they find something that could quite easily be fixed or tightened up chances are they will allow you to do that. My tester asked me to remove two wheel nuts from a front and rear wheel. Don't know what he was looking for but luckily I had my socket set. I would have taken the torque wrench as well if I'd known. I also took some photos of the seat belt mounts showing them to be 8.8 or high tensile material. The tester needs to know this and you don't want to have to be pulling the thing apart just to prove the case.

So, I had a pass. Tick, Gold Star. Big relief. I really didn't want to have to fork out more money for a retest, hire the trailer again and get up at a sparrow's fart to get the whole rig over to the test station, two hours drive away, for an 08:00 start.

Next up is to get the car registered. More form filling. Again AK have a very good section in their members area with a list of forms you need and examples of how to fill them in and where to send them. Check the latest fees for your vehicle licence. You also need a certificate of 'newness' from AK. If all goes well, a few weeks later you get your V5c log book and a registration number.

And with that, I'll leave you to imagine what to do next.

Sunday, 20 September 2020

Final Fit

With the car back from the spray shop it is time for the final fit to bring it all together.

Carpets

If you have the interior pack from AK, you'll have a roll of carpet and two tins of glue. You'll need 10 or 20 pack of Stanley blades (they blunt easy on the carpet and the fiberglass). I'm not a carpet fitter so I just made it up as I went along. Cutting long, fitting the carpet and then final trim to get it exact. The glue needs to be spread on both the carpet and the hard surface, leave 10 minutes and as soon as you bring the two within sniffing distance they will instantly grab and not let go. So you have to position the carpet exactly right before the two surfaces come together. I found the best way was to only coat half of the carpet piece, leaving one half that can be positioned and slid into place. Then smooth down the glued part. When fitted lift the unglued part, spread the glue and smooth down after 10 minutes.

If you have the luxury pack you'll have a piece of leather for the back panel. Put it in position and draw a line around the arc of the edge of the leather trim. It only covers part of the rear panel so you need to carpet the rest. Cut and fit the carpet to overlap the line by an inch or so. Now fit the leather covering. It probably will not exactly follow the arc of the scuttle but it is quite forgiving and can be persuaded into shape. Glue only a 6-8 inch square patch in the centre just to hold it in position. Now trim the carpet so that it overlaps the leather by just the depth of the trim edge otherwise you get an unsightly bump. Cut the leather panel around the centre tunnel. Leave the leather surface extended onto the console by 20mm but cat back the sponge pad underneath. On the console glue the leather down but where it meets the carpeted edge at the sides fold the leather back up and under to create a nice finish. Glue and smooth into position the rest of the leather panel.

Door cards

These will be covered with padded leather which makes it hard to fit back onto the door. Trim the sponge away from where the green clips fit. The card will now have a split in it to facilitate the padded pocket. At first sight it seems as if anything small will fall through and get lost, but after the card is fitted into place the thing squashes down and seals so nothing will fall though. You'll need to give the card a fair whack with your fist to get the green clips to engage properly.

Dashboard

This will now have a lovely padded leather finish if that is what you wanted. If it wasn't then something went wrong in translation, but assuming you are delighted then what will dampen the spirit is the fact that you are now going to have to take a very sharp knife to it to cut the holes for the instrument and lights.

The ignition switch has two flats on the barrel which help to hold it in place in the hole. With the leather padding, the nut at the back cannot be tightened enough to hold it in position. I made a small plate with a hole with flat sides that exactly fit the ign barrel. Then bond this into place on the rear surface of the dashboard and secure with two small screws. The ign barrel should now be solid. Now is the time to fit an immobiliser as you will need to be cutting into and T'ing off some of the critical wiring that make things work.

Seats

First get the seat belts bolted in. You'll need to drill through the body in a couple of places if AK have not pre drilled. Just look at the opposite hole and drill a pilot hole and feel for the threaded hole with a scribe. Then open up to fit the bolt. These need to be high tensile and are 7/16th UNF. You can fit collars to bridge the gap created by the body panel or just tighten the bolt and scrunch everything up so it is solid. Make sure the top seat belt mounts screw right into the support bracket, so cut the hole in the scuttle large enough for the 'eye' bolt to pas right through. apparently the IVA requires a certain distance between that and the lower part of the seat and we are close to the limit so the 'eye' bolt needs to be up as high as possible and the seat as low as possible.

It seems if slide rails are fitted for the seats now it will fail the IVA. Fit them with at least 2 inches clear between the back of the seat and the rear panel. This is to allow clearance to fit some head rests which will keep the IVA man happy. Use large washers to spread the load when passing bolts through the seat through into the floor pan. Everything will scrunch down and you'll end up with needing shorter bolts than you think. 35mm x 10mm bolts seem to work ok here.

Side Vents

AK will flog you a nice set of polished steel vents for the parallelogram hole in the side of the car. When fitted they will fail the IVA test. And if you don't fit them you will fail the IVA test (I think the testers knee will fit in the hole). So we'll need to cover up the sharp edges when we go for the test. These come as part of a IVA kit AK can loan you.

You will need four pieces of wood around 6-7 inches long and in the region of 15mm x 12mm cross section. Drill two holes in each of the flat bars which the vent blades are welded to. Screw the wood on such that it sits proud of the bar by around 3mm. What we need is a gap between the wood and the blades so that the wood will seat square on the inside of the body and not get caught up around the curved lip that protrudes internally around the hole. Check how the blades sit. I had mine sitting 2mm or 3mm inside the outer flat surface of the body so as to ensure there is definitely no protrusion. Plane or shave the wood accordingly so the vent blades sit square.

Insert the lower edge into the hole, push through and drop down until the top edge can rotate in. Now lift the unit up and pull into place. The offside looks tight what with the brake servo being there but there is actually plenty of room. When you do this for real, have a large splodge of P38/P40 along the face of the wood. Pull outwards to squash the wood against the inside of the body, and either tie it to a static object (a teenager with a mobile phone will do) or sit and hold it until the bonding hardens. When set remove the plastic that covers the shiny surface and admire.

Front Vents

Here we need some wire mesh. Halfords have some for a high price. I found some nice ally mesh on Amazon. The mesh holes are 16mm x 8mm and look quite pleasing when fitted.

Measure the hole and cut the measure to size around 20mm larger all round. The inside edge is right up against the inner wing so make sure it fits snugly here or there will be gaps. It is soft enough to push with finger tips to form the mesh around the edge of the lip and leave around 15-20mm overlay. This is where you will slop a load or P38 to secure it into place. Tie a couple bits of string to the outside of it and again tie to an immovable object. I didn't have a mobile phone bearing teenager so I tied the string through the holes for the nudge bars.

The rest is just assembling everything back on the car as was test fitted before it went for a coat of paint. Glue the boot and bonnet rubbers into place, fit the gear lever, align the headlights, titivate it, clean and polish it, get the neighbours round to admire it, and hope it starts up ok.

Saturday, 19 September 2020

Sunday, 12 July 2020

Preparation for paint shop

Sadly, a lot of it now has to be stripped off so it can get a coat of paint, assuming you don't have a gel coat base colour.

You can of course have anyone paint it but the chaps who hang out next door to AK know exactly how it's done and their work seems to be as good as it gets. Plus we can have AK look over the build and laugh/admire your work and suggest changes you may need to make, especially for the IVA test.

So, remove all lights, bars, windscreen, fuel filler, exhaust silencers, wash and wipers.

Remove the chrome cover on the door lock but leave the lock in place. Leave the rubber door trim in place. Leave the boot and bonnet rubbers in place. Leave off the inner cockpit panels. Remove the handbrake and tie the cable out of the way if you have the large Jag wheels fitted from the donor car.

The boot and bonnet gas struts must be fitted as well as the boot handle and the bonnet handles.

The work on the car will include improving the fit of doors, bonnet and boot and of course repairing, fixing up all blemishes etc on the body.

The inner skins of the boot lid and bonnet will be painted body colour if you wish.

As the above items are removed, check the clearance around the fitments. The paint will take up a millimetre or more so make sure everything has a reasonable clearance for when you refit.

Same with the dashboard. Make the holes for switches, instruments and lights up to 2mm larger to allow for the leather covering which will be folded into the holes, but maybe only 1mm for the small lights which are just a push fit.

At the same time, drop of the doors cards with the dashboard for the trimmer unless of course you have your own solution. Spend absolutely hours with Wendi choosing colours and the finish of the cockpit. Drink several cups of coffee, a few biscuits and when done make your way home to an empty garage/workshop and wonder what you are going to do for the next four weeks or more. In my case, decorate the kitchen.

Nudge Bars

They are IVA compliant, so I am reliably informed, and seem to be very good quality.

The rears are easy to fit. There are support brackets in place inside the boot and under the rear chassis rail. The rear bars from Europa come with tubes that fit through the body so we don't need separate chrome tubes here.

The holes are marked on the body, but check for exact location to get the bar central and level.

The holes are marked on the body, but check for exact location to get the bar central and level.Drill out the holes and go all the way through into the support brackets. Using some 10mm threaded tube, locate the bars into place. You may need some washers against the brackets to even up the bar if there is a difference in exact location of the brackets that are bonded into the body.

Here I have temporarily fitted with nuts in place of the over riders to get the positioning correct.

The front bars are more difficult. We will need to source some chrome tubing to cover over the 10mm threaded bars. AK will supply two right angle brackets to fit inside the inner wing.

First assemble the over riders onto the bar, then insert just the top two threaded bars into the upper holes of each over rider. Offer up to the body and when happy with it being central and level, drill the holes to 8mm. I started with 3mm drill perpendicular to the body surface, then a 6mm drill at an angle finally a 8mm drill angled in line with how the threaded bar will enter the body. Then open up with a round file until we are about 2mm larger than the threaded bar. Now we will have the exact position for the two lower holes once we have the bar in place and located in the upper holes.

First assemble the over riders onto the bar, then insert just the top two threaded bars into the upper holes of each over rider. Offer up to the body and when happy with it being central and level, drill the holes to 8mm. I started with 3mm drill perpendicular to the body surface, then a 6mm drill at an angle finally a 8mm drill angled in line with how the threaded bar will enter the body. Then open up with a round file until we are about 2mm larger than the threaded bar. Now we will have the exact position for the two lower holes once we have the bar in place and located in the upper holes.Fit the AK supplied bracket to the inner front wing and mark where the four threaded bars will meet with it. Here drill oversized holes as we'll need some variance to move around in whilst getting the bars dead central in the body work holes. Note that when tightening the brackets to the inner wing, they may distort and want to pull the threaded bars out of position so make sure everything is square.

Here we see the lower bar is set to low in the bodywork hole after mounting with the bracket.

That is ok as the hole needs to open up more to accept the chrome tube that will cover the threaded bar. So in that case I just open up the hole in one direction until the bar is central again and I have enough clearance for the chrome tube.

To save the wear and tear on the chrome tube, I used aluminium tubes of the same size to test fit and eek out the holes to the correct size.

I think next time I'll just go with over riders and lose the bars.

Monday, 6 July 2020

Bonnet and Boot lid

Boot lid

We probably need to file away some parts of the lip edge around the boot where the rubber sits in order to get the lid to sit flush with the body. So fit the rubber trim and mark where it needs to be relieved to get the lid to sit flush. I had to cut a fair amount away from the rear section. Be aware that where the lid protrudes it may not be right under there that the edge needs trimming. The lid can be held proud by an edge that needs filing down some inches away.

The boot lock, handle and hinges are from SandJ.

The hinges are slightly different left and right. Fit them so the upper surface of the hinge is horizontal. The surface they sit on falls away with the curve of the boot lid. Fit them nine inches either side of the centre line you have managed to work out and draw down the centre of the car.

You'll be wanting to fit the handle dead centre of the boot lid. So work out just what is dead centre and drill the hole. Open up to suit the boss at the back of the handle and make the small cutouts for the locating lugs. I bonded two nuts with washers on the inside of the lid so I didn't have to use self tap screws which may not be very robust.

You'll be wanting to fit the handle dead centre of the boot lid. So work out just what is dead centre and drill the hole. Open up to suit the boss at the back of the handle and make the small cutouts for the locating lugs. I bonded two nuts with washers on the inside of the lid so I didn't have to use self tap screws which may not be very robust.There may also be a possibility to drill and tap two holes into the lock mechanism so you can insert screws all the way through and screw into solid metal but I would need to take the thing apart to check if that is viable and I'm not doing that now it is all in place. The AK preference is to cut the small lugs off and drill for self tap screws. Apparently if the bonded nuts come loose when the handle is removed for painting it causes a fair amount of angst when putting it back again.

The position is dictated by the position of the square peg from the handle. Looking at the lock mechanism the square hole for the peg is offset, so it is a bit awkward to fit the bracket. It just about fits, the box could do with being slightly wider.

To make the fitting easier, I welded two nuts to the lock mechanism so I didn't have to cut the hole in the box so large as to fumble with loose nuts inside. When I do this again I'll weld the nuts to the other side of the plate which would make more sense.

To make the fitting easier, I welded two nuts to the lock mechanism so I didn't have to cut the hole in the box so large as to fumble with loose nuts inside. When I do this again I'll weld the nuts to the other side of the plate which would make more sense.If you cut the square peg to size before fitting, you won't need to drill right through the box section. After cutting down the square peg I filled in the hole ready for painting.

The catch that the arm locks into is mounted back up against the rear edge. In fact I had to cut a small section away to get it to sit back enough for the arm to properly engage.

Gas struts

I went a bit off message here. AK can supply gas struts and all the brackets to fit the bonnet and boot.

There are two reasons I went my own way on this and one of them is about doing stuff myself if I can. And as it turns out, I could. So I did. So there.

From SGS Engineering:

Two gas struts GSV6-150

Four 10mm metal ball stud T4

We need some brackets. For the bottom brackets I made a wire template to get the shape of the bracket which fits under the rim of the rain channel.

The resulting bracket looks a lot like this.

Two holes drilled for the screws that will attach through the rain gutter, and one 8mm hole for the lower ball joint.

Two holes drilled for the screws that will attach through the rain gutter, and one 8mm hole for the lower ball joint.

Fix in place by bonding with P38 and two screws. I was going to pop rivet but the nose of my new expensive rivet gun was too wide to get into the rain channel.

The brackets are made from 1.6mm thick stainless polished to give a brushed metal look. For positioning follow the guidelines from Jon's video in the member's area on the AK web site. So from the front edge of the boot, measure longitudinally back 16 and a half inches and mark this across on the left and right edges of the boot. Line up the middle of the bracket and fix in place with the P38 and rivets/screws.

For the top bracket I tried a number of solutions and ended up with this:

The bracket is in two pieces which are welded together. An 8mm hole is drilled for the 10mm ball joint and two small holes for self tap screws to go into the rib on the underside of the boot lid. I was going to bind this as well with P38 but the fit was so solid I left it with just the two screws. Not sure if the spray shop will want to remove them when they spray the inside of the lid.

The bracket is in two pieces which are welded together. An 8mm hole is drilled for the 10mm ball joint and two small holes for self tap screws to go into the rib on the underside of the boot lid. I was going to bind this as well with P38 but the fit was so solid I left it with just the two screws. Not sure if the spray shop will want to remove them when they spray the inside of the lid.

Mark on the body the centre line of the bottom bracket. Shut the lid and measure 10 inches back and mark the lid. Open the lid and fit the bracket so the centre line of the bracket is on the mark. If you have made the bracket correctly it should be a tight fit on the rib of the lid. Secure with two self tap screws and fit the strut

As before, the bracket is polished to a brushed metal look.

The gas rams need some gas bleeding out, quite a lot actually but do it equally on both struts and open the grub screw for a second at a time. It needs quite a push to get the strut to move so don't let too much out. Fit the struts and then fine tune it by letting gas out half a second at a time until the lid will close with a push. When the lid opens, you may find one strut reaches full extension before the other. So you may need to slightly adjust the position of one of them so they both reach full extension together.

The gas rams need some gas bleeding out, quite a lot actually but do it equally on both struts and open the grub screw for a second at a time. It needs quite a push to get the strut to move so don't let too much out. Fit the struts and then fine tune it by letting gas out half a second at a time until the lid will close with a push. When the lid opens, you may find one strut reaches full extension before the other. So you may need to slightly adjust the position of one of them so they both reach full extension together.If you do go too soft, return the strut to SGS and they will refill for around half the price of a new one.

Bonnet

I've gone a bit alternative with this. Gas rams on a bonnet? How very ostentatious.

As with the boot lid we need to fit the rubber surround and work out where to relieve the edge so the bonnet fits flush all round. I did this with the bonnet attached to the hinge that comes with the body so I could understand the final placement of the bonnet. Take notice of the front edge of the bonnet as you open and close. It may come close to or actually interfere with the body. The hinge is adjustable for location and it is obvious to move it rearward to increase the front gap if necessary. But there is more to it. The hinge can also be made to vary its location vertically, the holes it locates in are quite large and allow for a fair bit of movement. Moving the hinge vertically alters the profile of curve the bonnet will describe as it opens. So moving it up will increase the amount of vertical movement before it starts to move forward on its journey around the curve. This will help it clear the body in the first few inches of opening.

Bonnet locks. First decide what lock cams you want to use. There are two types. One long, the other short.

The short one means you will need to fit a bracket that extends a little way into the engine bay as the lock has to be set in a certain position through the rib in the bonnet. That being so, the short cam isn't long enough to reach under the rain gully.

I used the long version. But if you do, note that there is a possibility that if the bonnet happens to be shut with the locks in the 'engaged' position, they could mark the paintwork on the body.

I used the long version. But if you do, note that there is a possibility that if the bonnet happens to be shut with the locks in the 'engaged' position, they could mark the paintwork on the body.To avoid that I found I could position the handles far enough back so the cams just close down inside the body, but still protrude far enough to locate themselves under the rain gully.

So. mark and drill the holes for the handles, open up and cut the small cutouts for the locating pegs.

Be careful to get the square peg appearing through the ribbed section under the bonnet so you have room enough to set the fixing screws with nuts.

On one side the hole for the screw was on the edge of the curved rib so I had to shape the nut to fit the curve and then tighten the screw from above while holding the nut in place. But the finish looks ok.

On one side the hole for the screw was on the edge of the curved rib so I had to shape the nut to fit the curve and then tighten the screw from above while holding the nut in place. But the finish looks ok.Fit the locking cams and trim the square peg to size.

Since the cams now reach quite happily under the rain gully we don't need big brackets extending out into the bay area. But we can't leave the cams to constantly rub on the fibre glass as they open and close so make up some curved stainless steel covers and bond them into place with plenty of P38

Since the cams now reach quite happily under the rain gully we don't need big brackets extending out into the bay area. But we can't leave the cams to constantly rub on the fibre glass as they open and close so make up some curved stainless steel covers and bond them into place with plenty of P38

Finish off by painting them engine bay colour. Black in my case.

And here's how it looks

Gas struts

Well, there aren't any.

If you do fit them know that they will tend to push the bonnet out of place when shut, so you need to have them fitted when figuring out the fit of the bonnet. You also need them installed when the car goes to the paint shop.

I have a different solution to raising the bonnet and ensuring it stays up when it is raised. I was going to write it up but as I have not seen the same solution anywhere else I thought I would keep it as my own little USP.

Wednesday, 1 July 2020

Doors and Surrounds

Then fit the door lock using four 8mm nuts as spacers in place of the covered door card.

Make sure the door sits correctly when pressed shut against the door trim. Feel the edges are flush to the body and the door level is correct at the top rear where it meets the bodywork.

After removing the chrome cover, the four screw holes need to be opened up and on one of them the edge of the casting needs to be relieved to allow the countersunk screw (which AK supply and are screwed in place into the door when the body is delivered) to properly sit in place. Tape the lock handle in case it gets marked.

After removing the chrome cover, the four screw holes need to be opened up and on one of them the edge of the casting needs to be relieved to allow the countersunk screw (which AK supply and are screwed in place into the door when the body is delivered) to properly sit in place. Tape the lock handle in case it gets marked. Tape the door shut so it is tight against the rubber trim.

Tape the door shut so it is tight against the rubber trim.Assemble the catch into the curved backing plate and locate the catch solidly into the door lock.

A short length of tube or collar is required to fill the gap between the catch and the backing plate.

Allow a small gap between the curved backing plate and the door frame so we can get some P38 in there. Now screw the domed nut on finger tight. You should now see the final position of catch and plate.

Next. some woodworking. The catch plate needs some support or it will shift when your Significant Other gets out of the car after arguing about directions and she/he slams the door shut. To prevent that, either just agree with everything he/she says or cut/carve two pieces of wood which will jam into place between the curved backing plate and the bodywork. Don't carve it exactly as you want some space for P38 filling. So slather lots of it onto the curved plate, and all around the wooden blocks. When it is all in place and before it sets tighten up the domed nut behind the curved plate. Leave at least overnight as the P38 filling will be quite deep and needs a while to properly set. When done rub down the rough bits for finishing. The carpet will later fit over all this so make sure you have a bit of clearance or the carpet will be sticking out above the level of the door trim.

The other wooden blocks are to provide support to the panels AK flogged you with the body. You need to assess how thick they need to be in order to have the panels sit below the door trim, not up with it or along side. These will have a carpet covering and you don't want the edge of the carpet proud of the door trim. I have found that the door hinges interfere with this panel when it is placed against the scuttle uprights. It may be that some offsets are needed to bring the panel out a little away from the hinges. Also consider that the windscreen brackets will be down here. I cut some holes in the panel where the bolts holding the windscreen brackets are. The panel can screw into the wooden blocks and either tie wrap or self tap screws into the scuttle uprights.

The drivers side is the same story apart from carving the wooden blocks out to account for the battery cable and wiring loom.

Door Cards

More woodworking. The manual says 3mm ply but 3.6mm is more easily available and will do the job.

Don't just cut it equally 5mm in all around the edge of the door, it isn't an equal fit all round.

Shut the door and run a felt tip pen round the edge of the trim. That will be the line you need to cut the plywood to. It needs to be just off the edge of the trim but with no significant gap. When it is covered you want the door card to just press into the rubber trim so it seals.

Also leave a small gap at the top where it butts up against the moulding of the door.

Test fit the card to make sure it follows the line of the rubber trim and then sand a chamfer along the edge to give room for the covering when the door shuts.Drill holes for the lock mechanism and ten holes about 15mm in from the edge for the panel clips.

The manual recommends green clips from Woolies (no, not Woolworths - sadly) part number is CLIP 260.

When drilling these holes, only mark the centre point on the door, don't drill through the door. The holes in the door need to be offset about 10mm so remove the card, measure 9-10mm in from the hole centre and drill again. Mark each card so the trimmer knows which side is which.

After removing the card, refit the door lock with the 8mm nuts as spacres. Leave the chrome cover off until the car is back from the spray shop.

Friday, 5 June 2020

WindScreen Wipers and Washers

As per the AK manual, screen is fitted using a prop to get a 36 inch gap from the top of the screen to the rear of the cockpit. The rubber seal is quite hard to get in to place on the body when the screen is lowered into position. Spray or wipe a small amount of silicon lubricant (of the type that is used to lubricate side windows to run easy in their channels) along the rubber. The screen will sit down in the centre and leave a small gap each side which means the screen will 'rock' slightly around the centre. So, make sure the screen is set down as far as it can go in the centre, then on each side place a small spacer or wedge to get the gap even each side. The screen will then be exactly straight and level on the car.

G-clamp the stays into place on the scuttle uprights and drill through with 6.5mm drill. Now drill the stay with 8mm drill. Insert a 8mm tap and cut the thread in the scuttle. Now secure with 8mm 8.8 bolt. The same can be done with the upper bolt but as the scuttle is open backed here I just drilled 8mm all the way and secured with bolt and nyloc.

On the driver side, be careful locating the upper most bolt. The wiper motor sits here and there is zero clearance between it and the windscreen stay.

Wipers and wiper motor

The wiper blades have a "I'm only here for the IVA. Don't even think about taking me out in the rain" look about them but I'm sure they will be fine.

The splined stud and gear wheel mechanism has a plastic spacer tube cut at an angle. Check that they are both cut the same, I had to file one of mine so it presented the same angle. Check them against the angle of the chrome escutcheon, it should be the same. Use the spacer tube to define the angle of hole to make, and using the soft oblong gasket, position just in front of the windscreen rubber. I have a two wiper system so 10" either side if the centre line. Refer to AK manual for the three wiper system. Three wipers? Really?

The motor mechanism is a bit awkward. I had several attempts, this is how I did it.

Forget the rack (long wire that threads through the wheel mechanisms) for now.

Bolt the motor in place and get it as high up and tilted as much as possible so the nose of it (where the rack will come out) points at the first wheel housing under the first blade.

Align the wheel housings so the entry/exit points for the tube point at each other. Measure and cut the tube for the lengths from the motor to the first housing, then between each housing, and then cut a short piece, about 3" for the end bit.

It isn't strictly required to flare the ends as they are clamped in to position anyway, but if they should move, they can jam against the toothed wheel. Just create a small flare so they can engage in the housing. Assemble it all to check for alignment and correct length.

It isn't strictly required to flare the ends as they are clamped in to position anyway, but if they should move, they can jam against the toothed wheel. Just create a small flare so they can engage in the housing. Assemble it all to check for alignment and correct length.Now take motor off and assemble the rack into the mechanism. There is a small block that sits in the end of the nose and you should have a threaded collar that will locate the first tube onto the nose of the motor. Slap loads of grease in the wheel housings, the wiper motor gear and the rack itself. Thread the rack through each of the tubes and engaging with the toothed wheel. Mount the motor, again getting it to align with the first housing as best you can.

Now with the rack in the tubes, shape the tubes to get the best angle for the tubes into the housings. The thing is we don't want any sharp bends or edges for the rack to rub against. Apart from the angles between the motor and the first bracket, there is the curve of the body to reckon with. Gently press and form the tubes slightly to take account of these curves. Don't try to bend the tube without the rack in and don't use a pipe bender especially without the rack inside the tube. It will kink.

Now with the rack in the tubes, shape the tubes to get the best angle for the tubes into the housings. The thing is we don't want any sharp bends or edges for the rack to rub against. Apart from the angles between the motor and the first bracket, there is the curve of the body to reckon with. Gently press and form the tubes slightly to take account of these curves. Don't try to bend the tube without the rack in and don't use a pipe bender especially without the rack inside the tube. It will kink.Screen Wash

The package from Merlin is cost effective, light and tucks away in front of the passenger footwell.

And that's why I don't have a polished steel bottle sitting up front next to the radiator header.

It comes with black plastic washer jets that have two holes for two streams up onto the screen.

The wiper kit from S&J came with jets that have a chrome dome and perhaps look slightly nicer.

These jets have a movable ball to direct the stream up or down.

The washer jets are a bit urgent with the stream of water. With the pin hole at its lowest point the stream still cleared the top of the screen and soaked the cockpit. Relocating them closer to the screen would only give a small improvement as the bulkhead limits how close it can get to the screen.

The washer jets are a bit urgent with the stream of water. With the pin hole at its lowest point the stream still cleared the top of the screen and soaked the cockpit. Relocating them closer to the screen would only give a small improvement as the bulkhead limits how close it can get to the screen. These jets have a plastic spacer tube so just like the wiper mechanisms we can drill the hole at an agle of 3-5 degrees and then cut a similar angle from the top of the spacer. That will also leave a thin wedge shape available to go on the top side. In this was we can angle the jet so it hits dead centre of the screen.

These jets have a plastic spacer tube so just like the wiper mechanisms we can drill the hole at an agle of 3-5 degrees and then cut a similar angle from the top of the spacer. That will also leave a thin wedge shape available to go on the top side. In this was we can angle the jet so it hits dead centre of the screen.It works but not sure if it will stay.

The jet that came with the screen wash kit will probably be better, just that it's a bit black.

But it does have two jet outlets and looks cute.

Thursday, 28 May 2020

Engine First Start

This is all about a LS3, Omex ECU and cable throttle with Jenvey throttle body. Probably similar for Canems but the software for mapping is will be different I would think.

First the essentials.

Fuel in tank and all fuel line connections tight. Especially check the connection onto the fuel rail.

Check all coolant hoses are tight.

Remove fuel pump relay if you want to spin the engine over with no plugs in.

Coolant. Advised to use OAT (pink/red) coolant. You will need at least 11.5 litres. It comes in ready mix or concentrate.

Oil. The engine has a shallower sump from original so a little oil may need to be drained out.

It came pre-filled with oil so I have left that in place.

By now I have all electrics connected and wired up. I couldn't be arsed to frig up a temporary dashboard, oil gauge and all bits necessary to start the engine way back before I had the body on. So where I am now is all connected as per final setup and ready to go.

Taking the plugs out is a pain, especially with a GEN III chassis. Lord knows how I'm going to get them out to change at first service. Anyway, spinning the engine over doesn't always get the oil pressure going enough to register. I really wanted to know the oil pressure is going to be there so I rigged up an oil gallery priming solution.

At the front nearside of the block is an allen key head plug. Remove it and insert a 16mm hose adaptor. Connect to this a drill driven pump (from Ebay, natch). Drain two litres of oil into a clean container, prime the pump, connect up, switch ign on. With drill running at full revs the oil light went out and I saw ~20psi pressure. So this has given confidence the gauge and light sensors are working, and also that we have an engine primed with oil from top to bottom without having to turn the engine over.

At the front nearside of the block is an allen key head plug. Remove it and insert a 16mm hose adaptor. Connect to this a drill driven pump (from Ebay, natch). Drain two litres of oil into a clean container, prime the pump, connect up, switch ign on. With drill running at full revs the oil light went out and I saw ~20psi pressure. So this has given confidence the gauge and light sensors are working, and also that we have an engine primed with oil from top to bottom without having to turn the engine over.

The 16mm dia threaded adaptor is at the end of the hose and screwed into the oil gallery at the front nearside of the engine.

Now we need a laptop running Windows (although I didn't check software is available for Linux, but well done if you have Linux anyway) and a piece of software called MAP4000 downloaded from Omex web site. A USB to serial cable is also required unless you have an ancient laptop and have serial ports. There is nothing special about the cable, don't spend loads on a special cable, just a standard USB to RS232 9-pin male is fine.

So, install software, open it and drop down the ECU tab at the top, choose connection setting. If a port doesn't appear you may need to install drivers for USB to RS232. Select the port.

Switch on ign but don't start engine.

On the setup screen are TPS settings. Make a note of the RAW setting on the left of the screen. Click on TPS min value and change it to whatever RAW was plus 2. In my case RAW was 9 so I set TPS min to 11

Now push the throttle pedal to fully open and note the new RAW number. Now set TPS max to RAW plus 2.

That's it. Now press the start button. The throttle may need to be opened a little to get it off a lumpy tick over. It will get hot and smoke and smell like mad. This is normal. But not if it goes on too long.

I ran it for about 1 min and then shutdown. Check all fuel, water and oil connections, joints etc. Check under the car for pools of fluid. I was lucky to have no leaks anywhere. Touch each of the exhaust ports to see they are all same temperature, means it was firing on all 8 cylinders.

I now went through the TPS settings again as the RAW figure changed slightly.

There is a small allen screw on the front of the throttle mechanism. It is spring loaded and sets the opening for the butterfly in idle position. Try to feel where it first starts to engage and then screw in another half to one turn. Reset TPS min and max if necessary (these settings are with engine off).

Now run the engine again and bring it to temperature. Check the temp on the screen and on your dash gauge. I found my dash gauge lagged behind the laptop display but got there eventually.

Omex ECU sets the fan to come on at 95 degrees. Check that happens and that air is flowing from outside in. If not reverse the fan connections.

Shut down and check oil, water and again all connections.

The fuel mapping can wait until the engine has run a few thousand miles to loosen up but there is one thing we can do now. At the bottom of the setup screen there are values for the Lambda sensor in the headers. F.B.1 & F.B.2. Ideally we want these as close to zero as possible. Anything above 10 and it will have trouble with passing emissions test, as well as running in a sub optimal fashion.

If it is high (mine was 30 which is the upper level of the possible display) it is running too rich, we need to adjust.

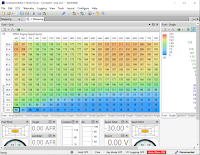

At the top left of the screen is a tab called 'Standard'. Pull down the twiddle at the side and select 'mapping'

We now have this screen. With the engine running on idle, at the bottom there will be a square highlighted with black edging. If the FB1 & FB2 readings on the first page are high, click on the square where the black edging is and lower the setting. Mine started at 40 and I ended up with 18. But lower it in increments, it doesn't like big jumps.

If the difference between two adjacent squares are then too much, the black edge will hunt around between the two. The engine may also be hunting. So click into the next square and lower that as well. Mine started out at 40, I lowered it to 20. Keep going back to the setup page to check the F.B settings, they will hunt around a bit but should be in the range 8 - 11, or if possible lower.

After this you may want to again adjust the throttle idle opening with the allen screw, and then adjust again the TPS min (leave TPS max as it is).

The thing is that when adjusting one setting, it is often the case that that will in turn require an adjustment elsewhere where before it was ok. It is a matter of tuning the figures to get a nice tickover and a low F.B value.

That should do until it goes in to a proper engine tuning specialist who knows what he's doing after a few thousand miles.